SunMax Energy, Inc.

My Business

San Jose, CA 95157

United States

Energy Saving Design / Durable Guarantee

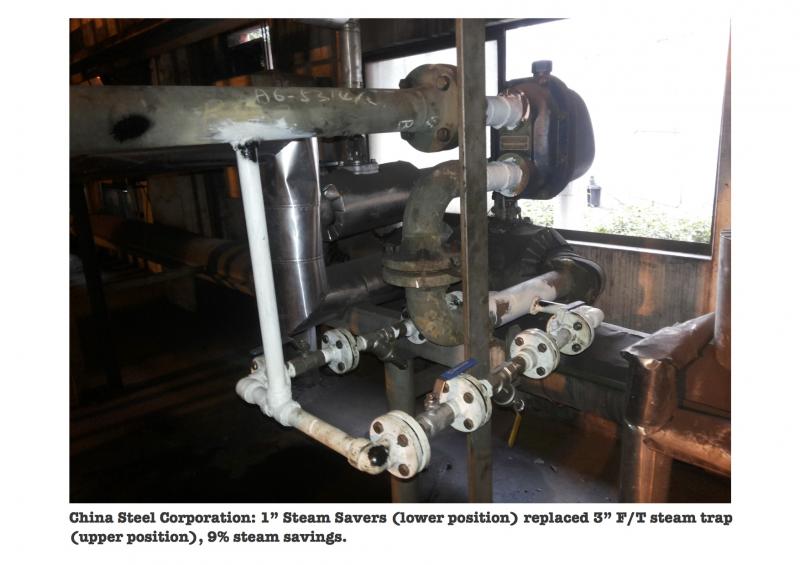

Steam Savers® are made of a solid, 300 series stainless steel bar. It contains no moving parts, corrosion resistance, and thus can be maintenance-free. Steam Savers® design is to accommodate the actual steam consumption, and to remove the condensate continuously. To guarantee the steam quality, while the steam energy consumed, the condensate must be removed continuously.

Compared with mechanical steam traps require regular inspection, replacement, maintenance, the difference is: Steam Savers® is maintenance free.

CPC_Utility_Plant.207175312_std.jpg)

Advanced Technology to Save Time and Money

Saving steam is saving money. Under different loads, Steam Savers® allows no more than 2 lbs./hr. live steam leakage, and the failure rate is zero. Mechanical steam trap has at least one-quarter inch opening hole. In using a year, this opening hole enlarges more than 10 times, and cause steam leakage more than 1.8 million lbs. a year. To fix any failure of mechanical steam traps, should take up labor, repair time, and delay production. After installed one year, in general, the mechanical steam traps failure rate is 42%. The maintenance to mechanical steam traps means waste time and money.

Steam Savers® has all the answer for your needs.

Certificate of PDA

(Product Design Assessment)

ABS

(American Bureau of Shipping)

Copyright 2015 SunMax Energy. All rights reserved.

My Business

San Jose, CA 95157

United States